When it comes to selecting fabrics for our upholstery or decor, we often think about texture, pattern, and durability. But one vital aspect often overlooked is lightfastness. Lightfastness, the ability of a material to resist fading or discoloration when exposed to light, can be the key to maintaining the vibrancy and longevity of our textiles. In this article, we'll delve into the significance of lightfastness in fabrics and discover how it can be achieved through innovative techniques and treatments.

Why Lightfastness Matters

Fabrics, like any other material, can fall victim to the harsh effects of light. The ultraviolet (UV) rays in natural sunlight and artificial light sources can lead to color fading, resulting in a lackluster appearance. Extended exposure to light can also weaken fibers, reduce fabric strength, and expedite the aging process in outdoor fabrics.

Whether its upholstery, curtains, or outdoor fabrics, textiles with exceptional lightfastness will keep their original colors for an extended period. This ensures a visually pleasing and well-preserved appearance. Fabric light hours signify the duration a fabric can withstand light exposure before significant fading or color change occurs. It's a measure of a fabric's lightfastness and indicates how long it can maintain its original color and appearance under specific lighting conditions. The exact number of fabric light hours can vary, depending on factors like fabric type, dyeing techniques, pigments used, and the intensity of the light source.

Factors Affecting Lightfastness

1. Fiber Type: Different fibers exhibit varying degrees of lightfastness. Natural fibers like cotton and linen may be less lightfast than synthetic fibers such as polyester, Olefin, and acrylic.

2. Dyeing Techniques: The method used to apply color to fabrics can impact their lightfastness. Dyes that penetrate deeply into the fibers or are chemically bonded tend to be more lightfast than surface-applied or loosely attached dyes.

3. Pigments and Additives: The choice of pigments and additives used during dyeing can greatly influence lightfastness. Some pigments offer better lightfastness, while certain additives enhance a fabric's resistance to fading.

4. Finishing Treatments: Specific finishing treatments, like UV inhibitors or light stabilizers, can significantly improve a fabric's lightfastness. These treatments create a protective shield that absorbs or reflects UV radiation, minimizing its impact on the fabric.

Enhancing Lightfastness:

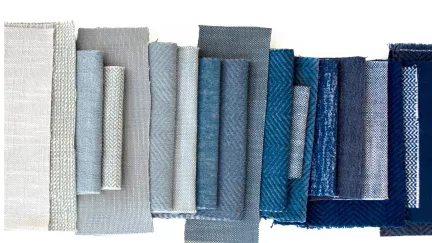

1. Fabric Selection: Opt for fabrics with inherent lightfastness properties or those treated for improved resistance to fading. Fabrics labeled as "UV-resistant" or "fade-resistant" are excellent choices for areas exposed to sunlight. Look for sample books specifically labeled for outdoor use, specs, and light hours. Check out our Outdoor Fabric Options for inspiration.

2. Testing and Certification: Look for fabrics that have undergone lightfastness testing by reputable organizations and manufacturers. Brands like InsideOut Performance Fabrics and Outdura offer fabrics with ultimate UV protection and light hours exceeding 1,100 hours.

3. Proper Care and Maintenance: Even fabrics with excellent lightfastness can be affected by prolonged sunlight exposure. Limit direct sunlight with window coverings or UV-protective films. Avoid exposing sensitive fabrics to extended outdoor conditions. Regular cleaning and proper storage help maintain fabric integrity. Our outdoor fabrics aren't just ideal for exterior spaces; their high-quality look and soft feel make them suitable for well-lit interiors too.

Considering lightfastness when choosing fabrics is essential for preserving their brilliant colors and extending their lifespan. By understanding the factors influencing lightfastness and implementing these strategies, we can make informed decisions and enjoy fabrics that endure the test of time, brightening our lives with their enduring beauty. Your choices reflect your creative vision, and lightfast fabrics ensure that vision remains captivating for years to come.